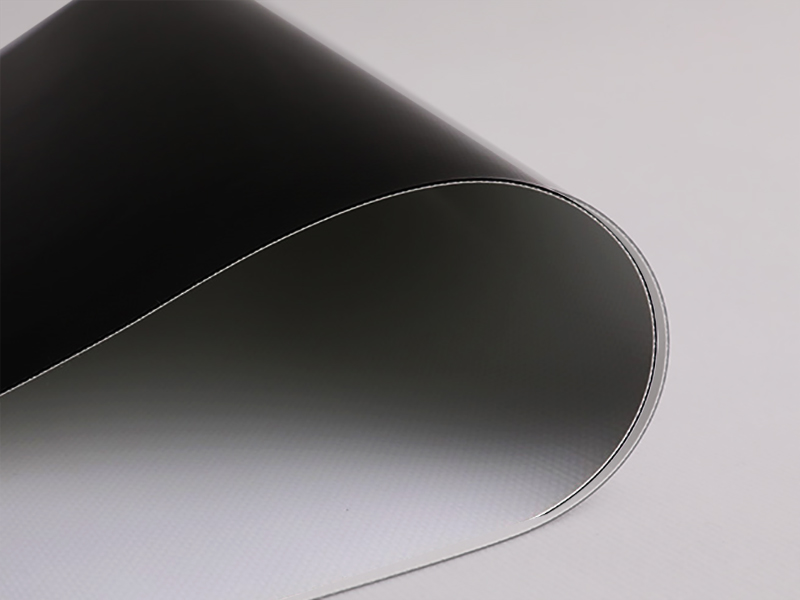

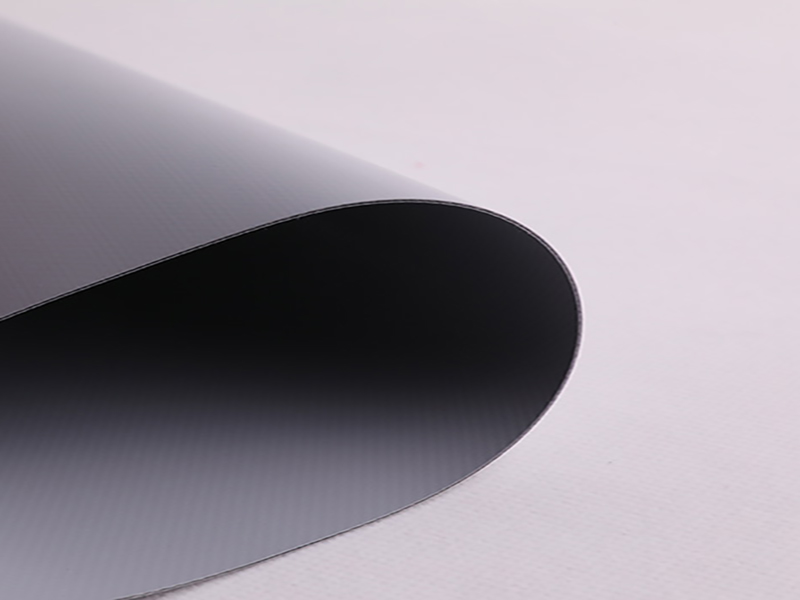

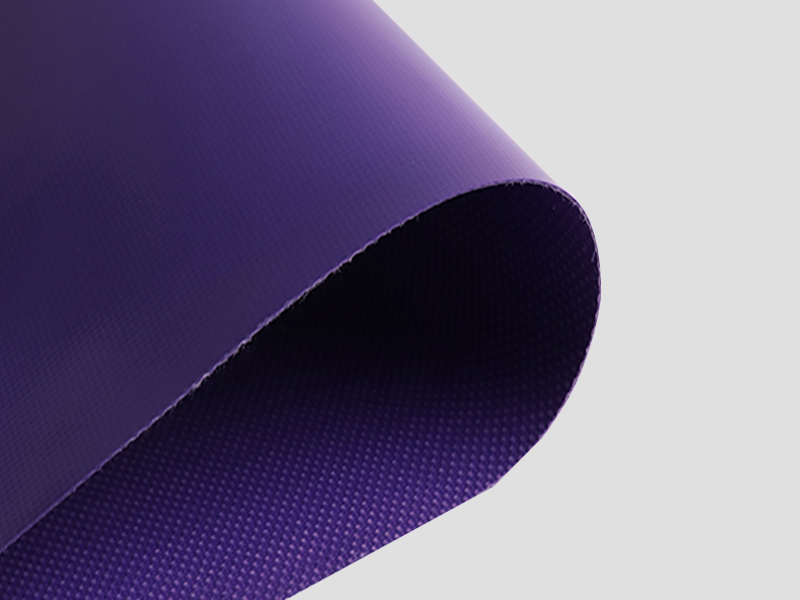

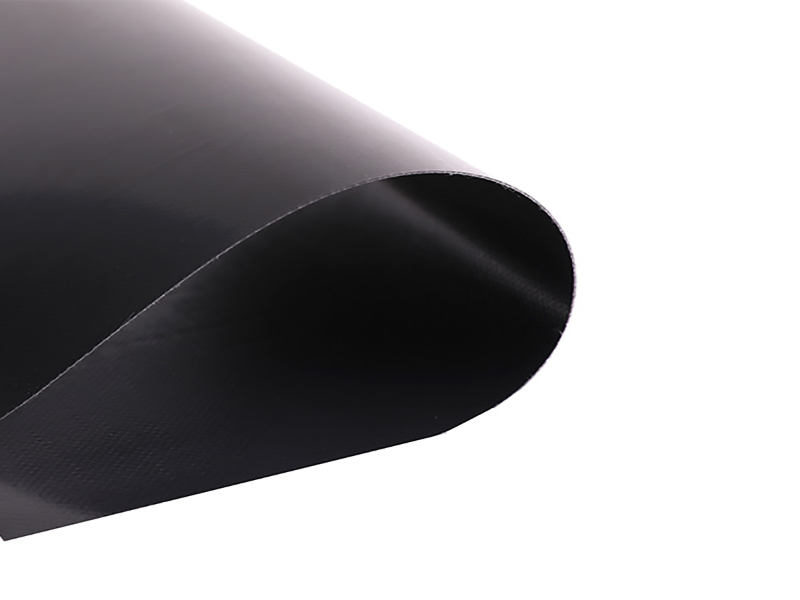

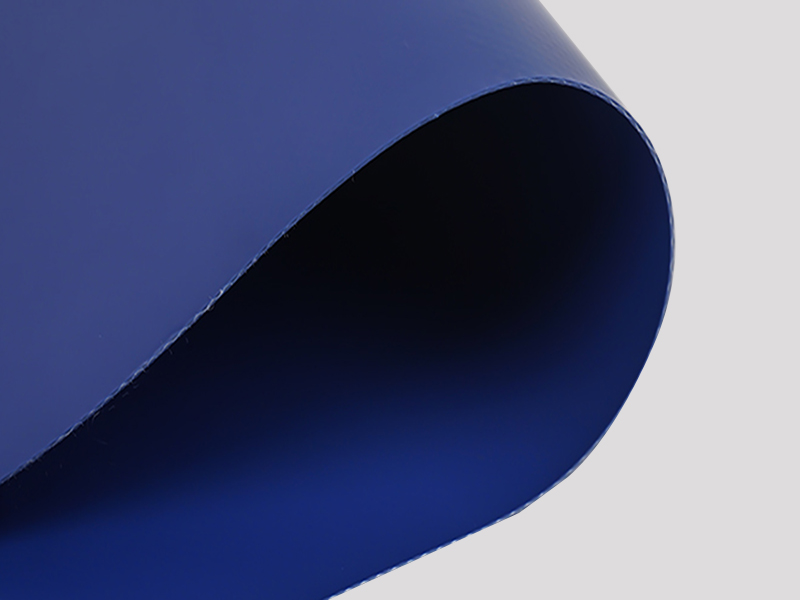

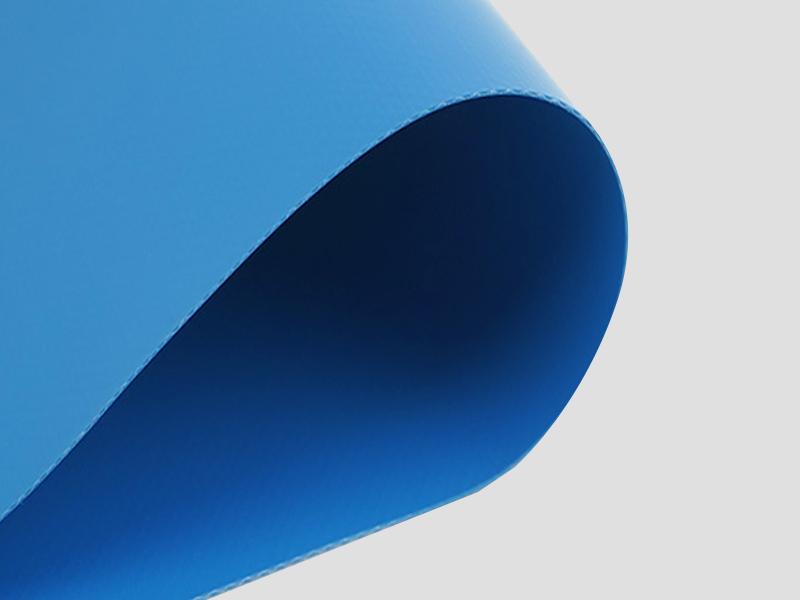

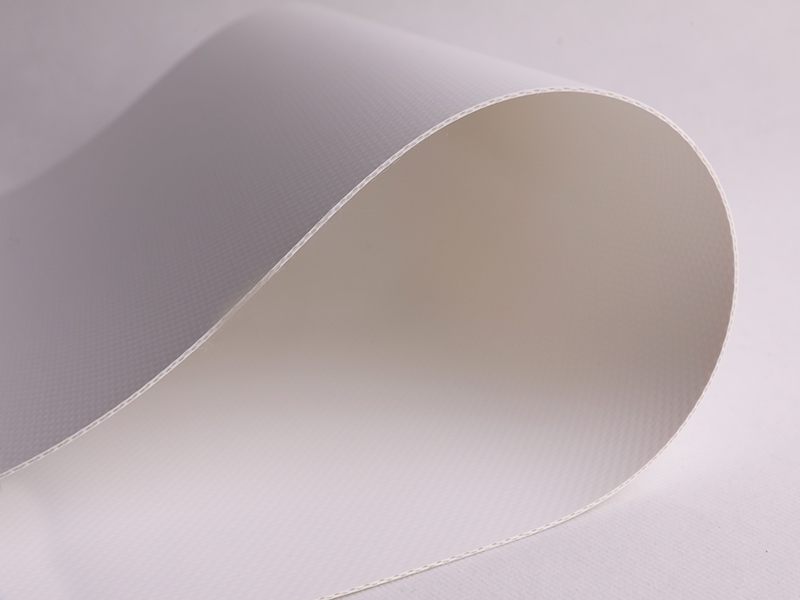

PTFE architectural membrane material is made of imported glass fiber cloth coated with PTFE resin.

The PTFE membrane structure is a brand-new form of building structure, which integrates architecture, structural mechanics, fine chemical engineering and material science, computer technology, etc., with high technical content. Its curved surface can be arbitrarily changed according to the architect's design needs, combined with the overall environment, to build a landmark image project. Under the sunlight, the interior of the building covered by the film is full of natural diffused light, and there is no strong contrast between the shiny surface and the shadow, and the visual environment of the indoor space is open and harmonious. At night, the lights in the building illuminate the night sky through the roof membrane, and the shape of the building shows a dreamlike effect.

The biggest feature of PTFE architectural membranes is high strength, good durability, fire and flame retardancy, good self-cleaning, not affected by ultraviolet rays, and a service life of more than 45 years. It has high light transmittance and little heat absorption. It is precisely because of the invention of this trans-epoch membrane material that the membrane structure building has become a modern permanent building. Widely used in large public facilities: roof systems of stadiums, airport halls, exhibition centers, platforms, etc.

Established in 2001, Zhejiang Xingyida Reinforced Material Co., Ltd has become one of the leading manufacturers of coated fabrics and industrial textiles in China. The main products are architectural membranes, tarpaulins, awnings, tent material, inflatable fabrics and industrial base fabrics. Our manufacture plant, located in Haining City, 100km apart from Shanghai, covers an area of 25, 000 square meters and enjoys great convenient traffic with two national highways nearby.