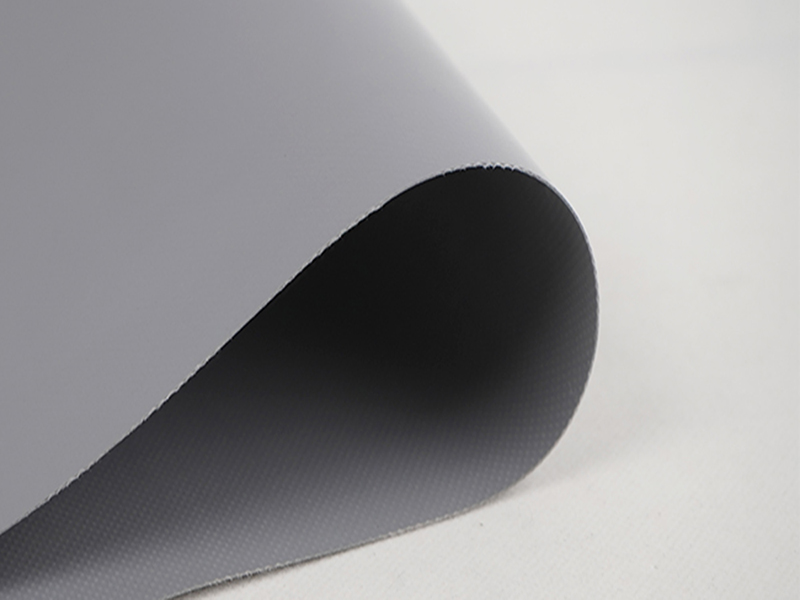

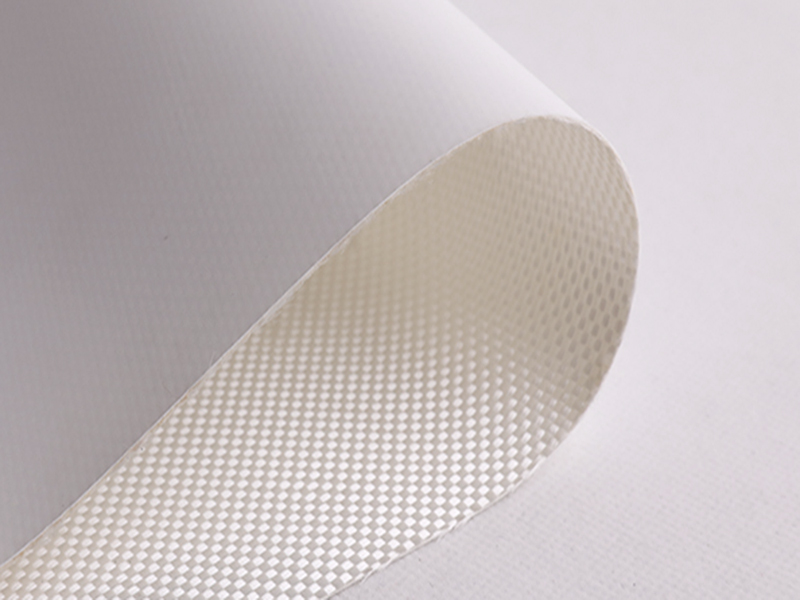

The definition of pvc tarpaulin is: a thicker cotton fabric or linen fabric. The tarpaulin was originally named after being used for sails. Generally, plain weave is used, a small amount of twill weave is used, and the warp and weft yarns are woven with multi-strand threads.

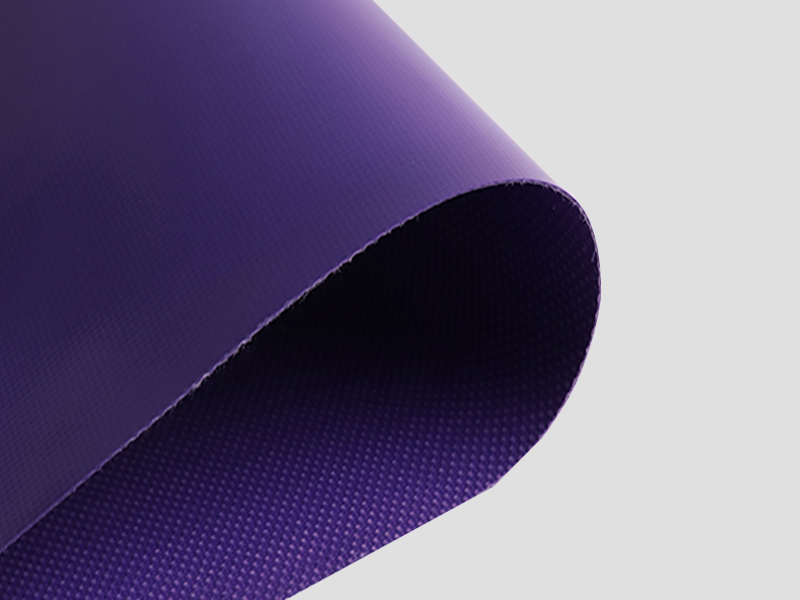

In general, tarpaulins are usually divided into two categories: coarse tarpaulins and fine tarpaulins.

1. Coarse tarpaulin is also called tarpaulin, the hardness and folding of the fabric, with good waterproof performance, used for transport vehicles and open-air storage cover and camping tents;

2. Exquisite tarpaulin ejection yarn is used to manufacture labor insurance clothing and supplies, and can also be used as shoes, travel bags, backpacks and other fabrics after dyeing.

In addition, there are rubber tarpaulins, fire protection, radiation shielding tarpaulins, tarpaulins for paper machines.

The tarpaulin has the characteristics of rain, warm, cold, etc., waterproof performance and breathable performance. The benefits of tarpaulins.

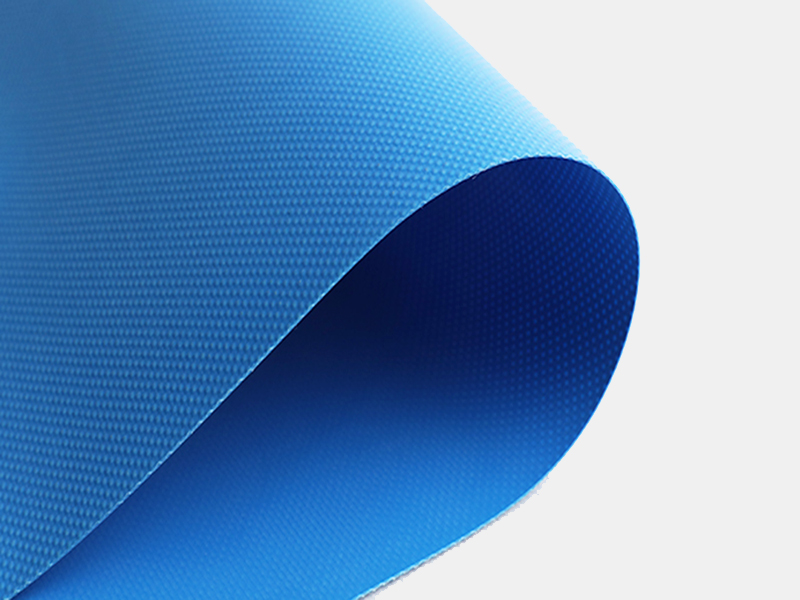

What are the performance characteristics of pvc tarpaulins sold in the market?

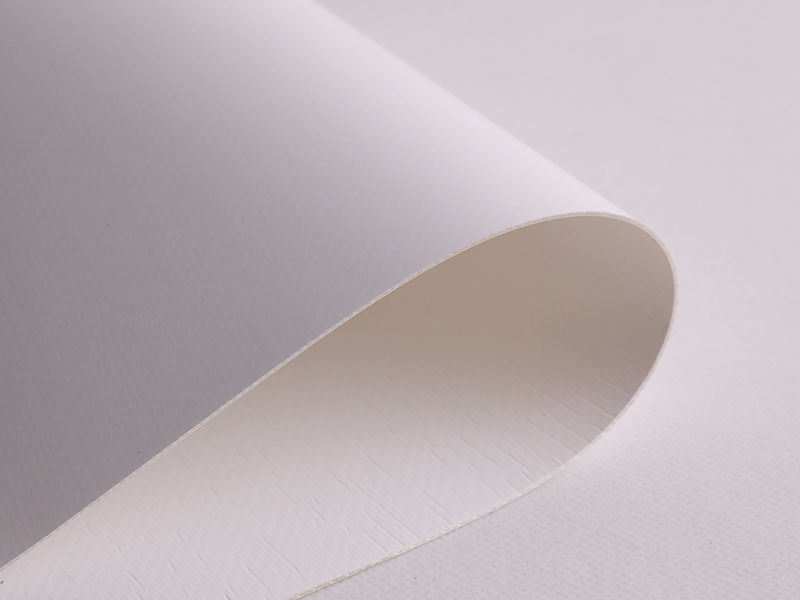

Tensile and dimensional stability: As a roof canopy and marquee, the tension is often used. The elongation of this substance is not too great, and its dimensional stability depends on the creep properties of the material.

Tear strength: The breakage of tarpaulin is mainly caused by tearing, so tear strength is an important indicator of tarpaulin. Tear strength is related to whether the tarpaulin will burst due to the influence of an external object, or for some reason, by expanding the surrounding holes, forming a large structural crack. So when the voltage is great. Must have high tensile strength and high rake strength.

Water resistance: Water resistance is an important element of the tarpaulin, by impregnating, vinyl chloride wood fat fills the pores of the fabric to form a coating film. If the resin adhesion per unit area exceeds a certain level, water resistance is not a problem. If the coating film is thin, through bending, soft friction or surface abrasion, the coating is easily broken, which will cause mud.