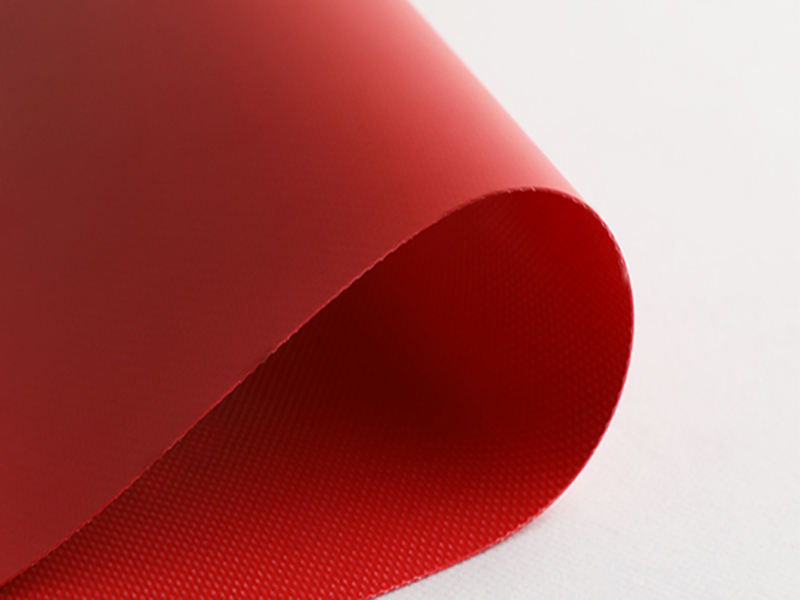

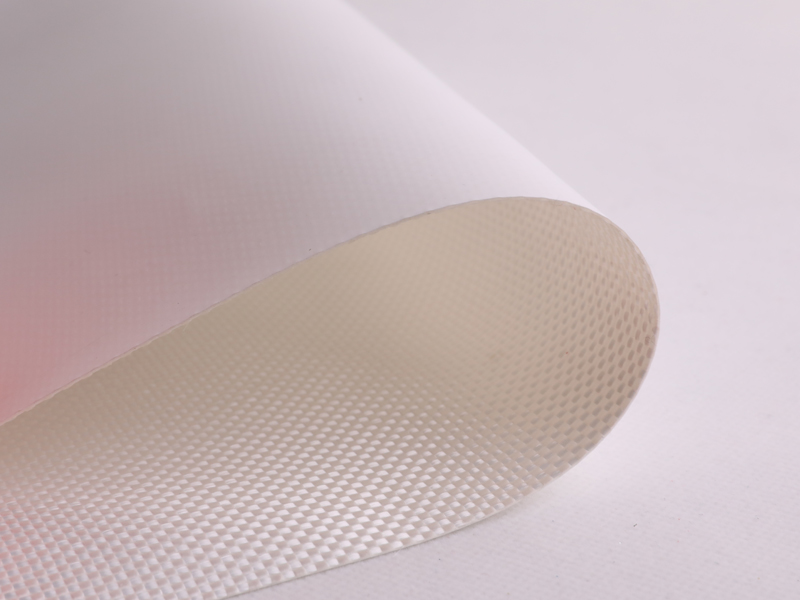

The definition of pvc tarpaulin is: a thicker cotton fabric or linen fabric. Tarpaulin was originally used for sails and got its name. It usually uses plain weave, a small amount of twill weave, and warp and weft yarns are woven with multiple strands.

In general, tarpaulins are usually divided into two categories: coarse tarpaulins and fine tarpaulins.

1. Coarse tarpaulin is also called tarpaulin, the hardness and folding of the fabric have good waterproof performance, and it is used for transportation vehicles and outdoor storage coverage and camping tents;

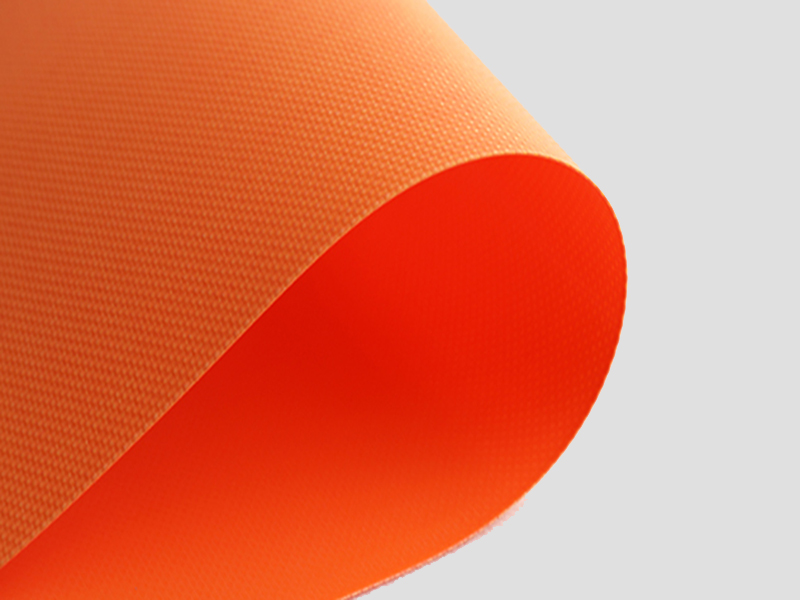

2. The exquisite tarpaulin injection yarn is used to make labor protection clothing and supplies. After dyeing, it can also be used as fabrics for shoes, travel bags, backpacks, etc.

In addition, there are rubber tarpaulins, fire protection, radiation shielding tarpaulins, and paper machine tarpaulins.

Tarpaulin has the characteristics of rain, warmth, cold, etc., waterproof and breathable performance, in terms of anti-condensation, acid and alkali resistance, mildew resistance, anticorrosion, weatherproof, flame retardant, fireproof, high strength, wear resistance, longevity, etc., it is The benefits of tarpaulin.

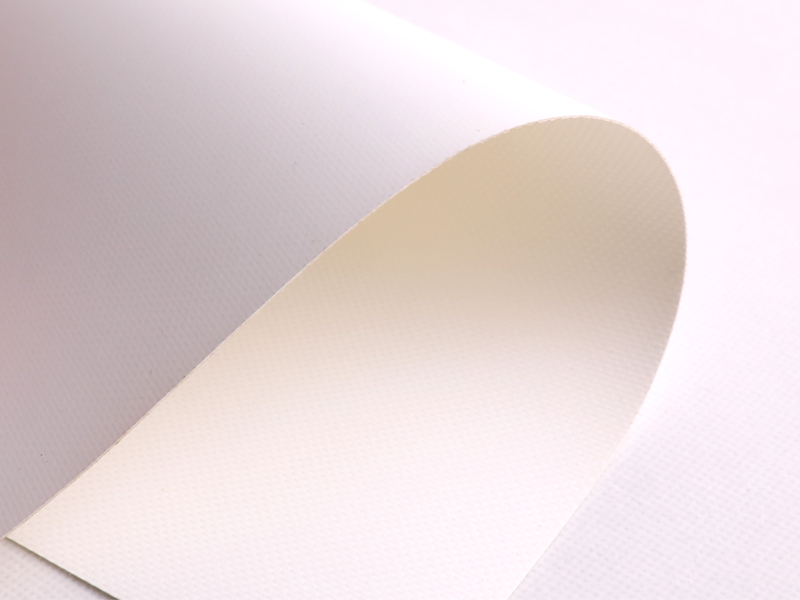

What are the performance characteristics of pvc tarpaulins sold on the market?

1. Air permeability: The permeability of tarpaulin must be considered, especially military tent tablecloth, the fabric structure of the shadow factor of permeability, density, material, type of waterproof finishing agent, resin adhesion. As the resin adhesion increases, the permeability of the tarpaulin decreases. Of course, this is related to the use of finishing agents. Generally speaking, breathable tents are mainly made of cotton, vinylon, lacquer and other products that have been treated with paraffin wax or acrylic resin.

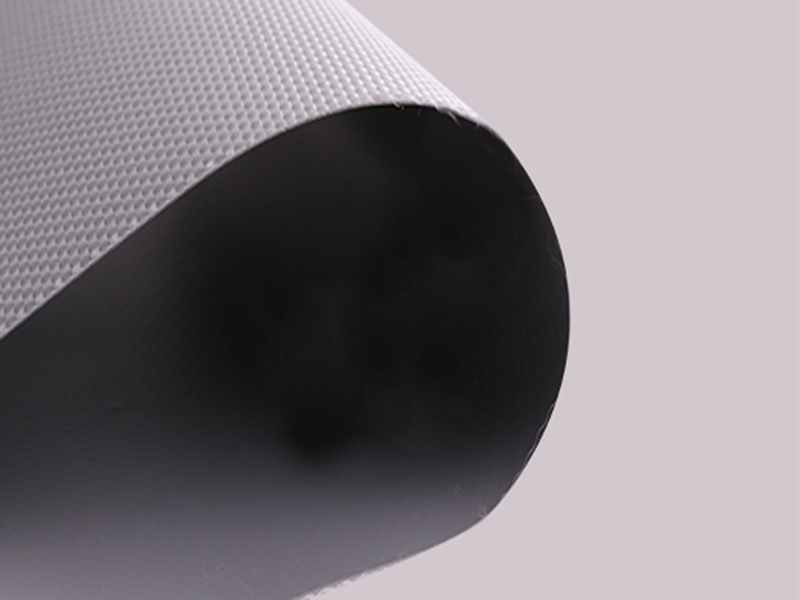

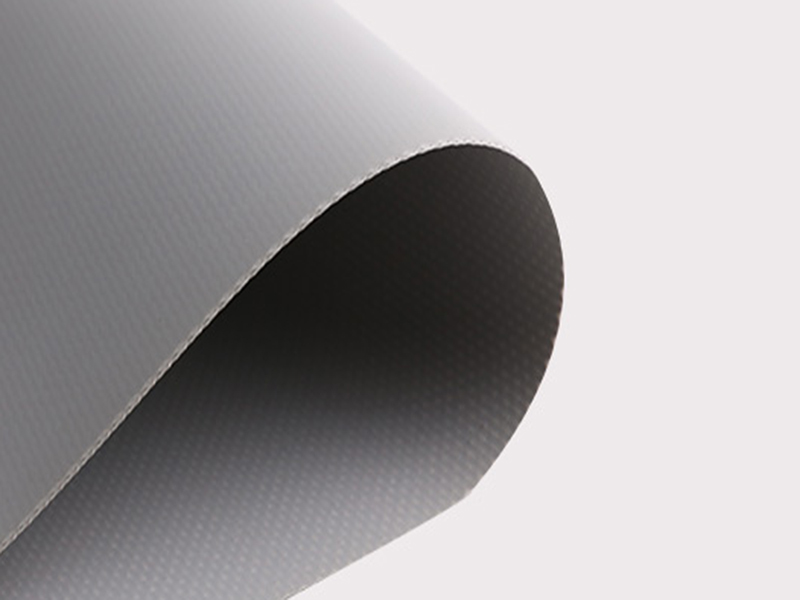

2. Tensile strength: When the tarpaulin uses various tensions, such as clamping force: additional force such as wind and rain during use. Despite these external forces, they are still required to keep their original form, not easily deformed, require higher tensile strength of the tarp, and should not be too large for the difference in tensile strength between width and length. Especially the tensile strength of large tents used as inflatable buildings is very important. Generally speaking, the base fabric is made of long-fiber fabrics such as high-strength polyester and vinylon. Waterproof finishing of vinyl chloride resin and chlorinated sulfonated polyethylene resin. The strength of the product mainly depends on the strength of the fiber material and the density of the fabric.

3. Stretching and dimensional stability: As a roof canopy and large tent, it is often used for tension. The elongation of the material is not too large, and its dimensional stability depends on the creep characteristics of the material.

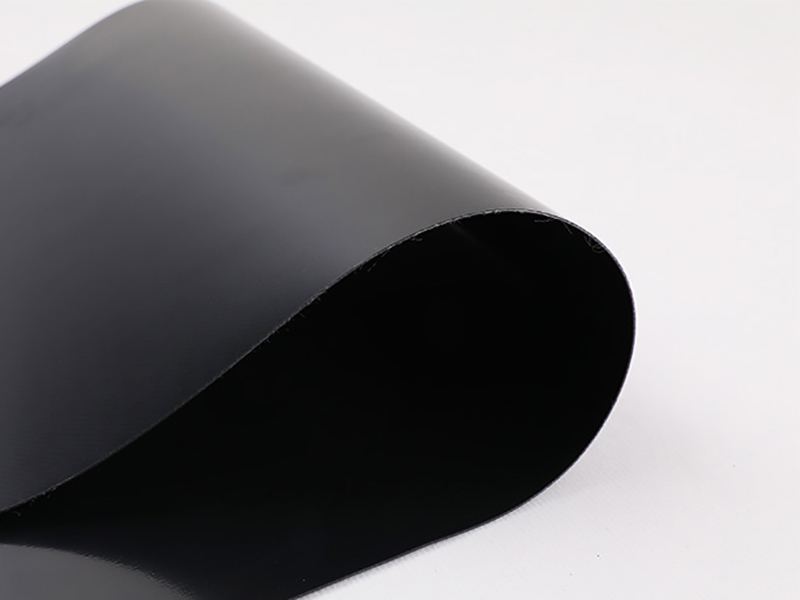

4. Tear strength: The damage of the tarpaulin is mainly caused by tearing, so the tear strength is an important indicator of the tarpaulin. The tear strength is related to whether the tarpaulin will burst due to the influence of external objects, or for some reason, expanding the surrounding holes and forming a large structural crack. Therefore, when the voltage is great. Must have higher tensile strength and higher rake strength.

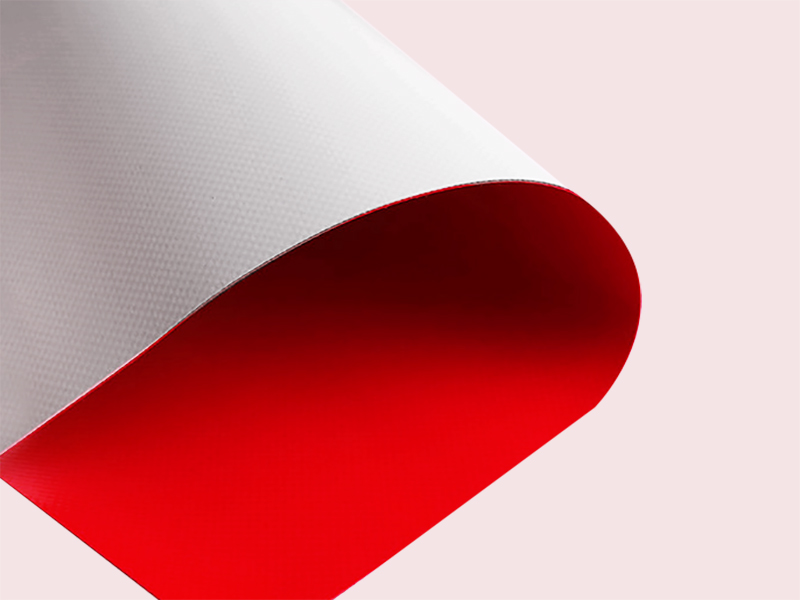

5. Water resistance: Waterproof is an important element of the tarpaulin. It is impregnated and filled with wood fat of vinyl chloride in the holes of the fabric to form a coating film. If the resin adhesion per unit area exceeds a certain level, water resistance is not a problem. If the coating film is thin, the coating is easily broken through bending, soft friction or surface abrasion, which may cause mud.

6. Flame-retardant: From the mountain where it is safe to use, the tarpaulin has good flame-retardant requirements. By choosing flame-retardant fiber and flame-retardant matrix, flame retardant can be achieved. It can also achieve the purpose of coating by adding flame retardants. The amount of flame retardant added is directly related to the flame-retardant effect.